Just last weekend a story hit the headlines that was the press equivalent of watching a train wreck in slow motion. Consuming column inches from tabloids to broadsheets on both sides of the Pond, the Case of the Giant Tapeworm fascinated fish foodies and pesca-phobes in equal measure. Arriving at a Fresno, California, emergency room, a mercifully anonymous patient suffering a ‘bout of bloody diarrhoea’ produced a bag containing the still warm remains of a freshly deceased tapeworm, a parasite measuring 5ft 6in in length that he had – shall we say, evicted – from his own body. When originally bagged and tagged, the creature was alive and kicking but apparently became ‘non-viable,’ as the parlance has it, en route to the hospital. Fortunately, the human host did not, was treated with a common deworming medication, and sent on his presumably lighter way.(1)

Although intestinal parasites are scarcely news, this particular case has gripped the reading public due, in large measure, to the large measure of the creature involved. At 5ft 6in, the worm was close in length to its host’s height which had even casual readers of the myriad pieces on this story wondering how it went undetected for so long. The unfortunate patient, a daily consumer of sushi and sashimi, had been in discomfort for months but assumed the sensations were those of routine GI distress and continued to eat raw fish, especially salmon. Somehow we sense he may be about to start varying his diet…

Frequently touted as an alternative to red meat, fish is inherently lower in fat and, with the romantic appeal of being a wild and untamed resource, sockeye salmon or blue fin tuna often find themselves on the ‘healthy options’ sections of restaurant menus. But does the hype live up to the reality? Given that fifty percent of the fish we consume are as likely to have seen the open ocean as the average palmato gecko of the hyper-arid Namib, are intensively farmed fish a good dietary option? Let’s take a look…

The history of fishing is arguably as long as that of our species, with early man deriving protein from river or coastal dwelling creatures. But as we have evolved, so has the industry. Today, commercial fishing is big business and the days of catching fish on a line or even of trawlers bringing in a catch are rapidly drawing to a close. As the populations of wild fish dwindle and grow harder to find and as corporate profit margins shrink commensurately, the 21st century solution no longer involves months’ long expeditions at sea but instead brings the fish to us. Intensive farming in controlled facilities is the new face of the seafood industry and they’re known as aquafarms.

With thousands of fish spawned and reared in cramped conditions, disease and pollution is inevitable

It may come as some surprise to know that sea creatures – from the lowly mussel to trout or salmon – are farmed as intensively, and often with the same detrimental effects, as their land-based porcine or bovine cousins. Indeed, according to Daniel Pauly, professor of fisheries at the University of British Columbia in Vancouver, aquaculture facilities may be likened to ‘floating pig farms.’(2) With thousands of fish spawned and reared in cramped conditions, disease and pollution is inevitable and, of course, takes it toll on the health and welfare of the animals and the quality of the water in which they live. Nitrates, ammonia, nitrites and ‘suspended solids’ (do we really need to explain what that means?) are ubiquitous in land-based aquafarms and allow for bacterial infection, parasitic infestation, and aquatic superbugs. In fact, one particularly unsavory problem with confined enclosures is the prevalence of parasites such as sea lice which eat at the flesh of the fish causing large sores, even eating through to the facial bone in what is known in the industry as a ‘death crown.’

To combat this, fish often receive large doses of antibiotics

– the very same class of drugs against which consumers rail when they are added to the feed of land-based farmed animals for the same purposes. With fish, however, the problem is even more complex given the political landscape of the industry. On the global scale, China leads the way in intensively raising fish for both for the domestic and international markets, supplying a full 70% of all aquacultural products and 55% of the export market. And, of course, food safety standards are very different in China than they are in the U.S. It is common practice, for example, for Chinese farmers to use known carcinogens such as nitrofuran, malachite green, gentian violet to treat fungal infections. Additionally, the use of antibiotics is widespread, with drugs such as fluoroquinolone (which, under lab conditions, has been shown to increase antibiotic resistance) routinely available.

…if we consume its flesh, this contamination ends up on our plates and in our sandwiches.

And then there’s the question of mercury. Well known as a problem for long-living, wild-caught ocean-goers like tuna and swordfish, mercury is another common contaminant found in intensively farmed fish. A neurotoxin that causes brain, kidney, and developmental problems, mercury is absorbed by creatures low on the food chain which are then eaten by progressively larger animals in whose tissues the toxin concentrates. By the time a fish reaches slaughter weight, it will have absorbed the mercury contamination of every smaller fish it has ever eaten and, if we consume its flesh, this contamination ends up on our plates and in our sandwiches.

The third major contamination source for factory-farmed seafood comes from the location of facilities.

Aquaculture farms are often sited proximal to near-shore waters which are prone to pollution from agricultural run-off, exposing the stocks to polychlorinated biphenyls (PCBs) and dioxins. Interestingly the domestic production of PCBs was banned by Congress in 1979 but these probable carcinogens persist in large bodies of water (such as the Great Lakes region) and in rivers. Despite remediation efforts such as the on-going and controversial dredging of the Hudson River in NY which, to date, has cost General Electric Co. approximately $1.7 billion, PCBs live up to their name as persistent organic pollutants. Their make-up allows them to readily penetrate skin, PVC, and latex materials, and they remain in the body – both human or piscine – as fat soluble compounds.(3) In humans, they cause hepatic damage, dermal toxicity, reproductive and developmental damage, thyroid problems, fatty liver, and ‘acute lethality’ – death, we assume.(4)

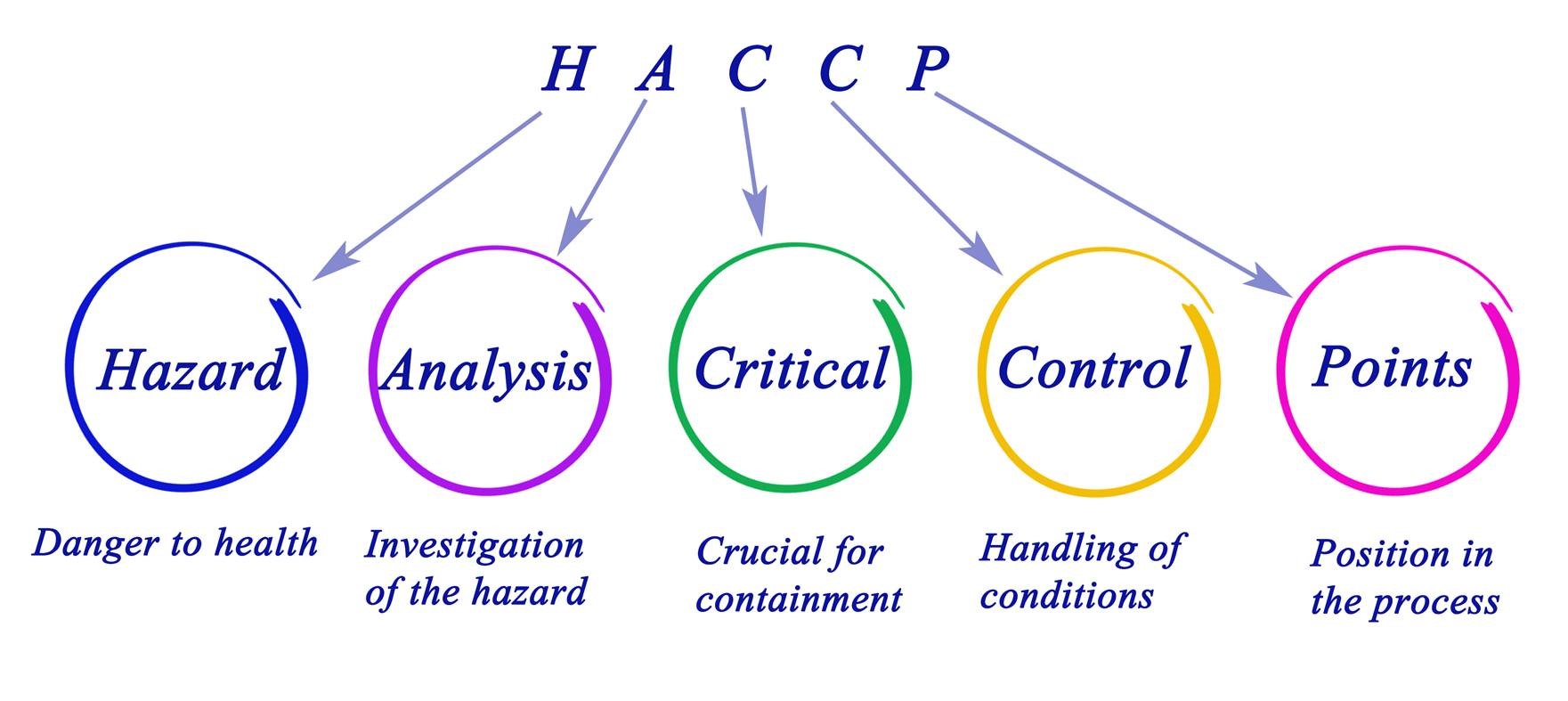

So what is the take away? Like seafood itself, contamination comes in many shapes and guises but what doesn’t vary is the position of governmental and regulatory bodies vis à vis the control of the industry. Key players in this arena are, of course, the federal Food and Drug Administration (FDA) and the United States Department of Agriculture (USDA) which both offer guidance in the form of HACCP regulation, cGMP information, and the power of product recall. As far back as 1995 the FDA published its final rule 21 CFR 123 ‘Procedures for Safe and Sanitary Processing and Importing of Fish and Fishery Products’ requiring the implementation of full Hazard and Critical Control Point (HACCP) systems.(5) This guideline, and its subsequent addendum The ‘HACCP Regulation for Fish and Fishery Products: Questions and Answers,’ details hazard analysis, corrective actions, current good manufacturing practices, sanitation control procedures, MOUs, employee training, requirements for imported products, and the shape of importer records and compliance.

Using existing fish muscle tissue, the company isolates specific cell types that grow quickly and differentiate naturally.

On the face of it, it would seem that the regulations are relatively comprehensive but, as with many issues of food safety for imports from overseas markets, we are constantly playing catch-up, reacting to blazes when they flare without getting ahead of the wildfire that the potential of foodborne contamination brings. So it’s tempting to think that perhaps the only solution is to abstain from seafood altogether, renouncing that salmon maki in favor of the perhaps safer natto roll. But there is a third way. Joining ventures such as MosaMeat in the Netherlands, SuperMeat in Israel, and Intregriculture in Japan, Finless Foods, based in that U.S. epicenter of the cell-cultured meat future for humans and pets alike, San Francisco’s Bay Area, is garnering some interest. Co-founded by two molecular biologists Mike Seldon and Brian Wyrwas who first crossed paths at the University of Massachusetts, Amherst, Finless Foods aims to do for fish what clean meat start-ups like Memphis Meats and Hampton Creek with their chicken-free chicken products have done for land-based creatures. Using existing fish muscle tissue, the company isolates specific cell types that grow quickly and differentiate naturally. Seeded on a scaffold of food grade materials termed an extra cellular matrix (ECM) the stem cells divide and increase in numbers until they are changed into either muscle or fat cells. Isolating the muscle cells allows each one to grow into more than 1,000,000,000,000 – that’s 1 trillion, in case you are counting the zeros – muscle cells in a medium comprised of ‘standard food-grade salts and sugars, and proteins – or growth factors – which are signals that help the cells proliferate. [These] are created in-house.’(6)

“We’re creating fish in sterile conditions so you don’t have the same challenges with bacteria and infections or food-borne pathogens…”

In terms of sheer volume, the 1:1 trillion ratio is an impressive start. But what’s even more exciting about this bioreactor-based technology is that in addition to offering ‘clean’ products untainted by mercury, antibiotics, or plastics, Finless Foods also aims to create exactly what the customer actively desires in their food. From leaner fish to more fatty options, the company is forging cost-effective ways to custom tailor their products to very specific tastes. And perhaps this may be the route to broader public acceptance of what many still regard as overly-engineered Frankenfoods. By offering a safe, healthy, and palatable – the company says ‘delicious’ – option for the risk-averse diner, Finless Foods wants to emphasize the myriad advantages to cell-cultured meats, created on what they hope will be a massive scale in brewery-like conditions. As co-founder Mike Selden commented: “We’re creating fish in sterile conditions so you don’t have the same challenges with bacteria and infections or food-borne pathogens, which also means it lasts longer with less spoilage. […it’s] also cleaner for the environment…no giant fish farms with pesticides and herbicides, and there’s no slaughter.”(7)

But what about oversight and regulation? Again Selden is committed to transparency and does not foresee obstacles: “We don’t anticipate any major issues, but we’re working closely with FDA and we’ll also be publishing toxicity tests to reassure people about the safety of our products. But just as important is that we want to have an open conversation with the public about this, so we can prove that what we are doing is safe and properly regulated.”(8)

A fish filet from a bio-reactor? Sure, we’ll take one…and throw in a side of extra-large fries!

Although cell-cultured fish products are in their infancy and will still need to jump through a few regulatory hoops and straddle public acceptance hurdles, the trail has already been blazed by companies dedicated to removing land animals from the dinner equation. As Mike Post of Mosa Meats illustrated with his slaughter-free beef burger, the technology does exist to create animal-identical options without the need for the cruelty, suffering, and waste of land, water, and feed resources that traditional agriculture inevitably entails. With natural fish stocks declining and millions of people around the globe relying on the ocean’s bounty for their actual survival rather than their gustatory satisfaction, it just might be time to embrace this high-tech alternative. A fish filet from a bio-reactor? Sure, we’ll take one…and throw in a side of extra-large fries!

Frankenfood or the latest resource in the fight against aquatic population decline and world hunger? Would you be interested in frying fish engineered in a clean environment? We’d love to know your thoughts!

References:

- https://www.theguardian.com/us-news/2018/jan/20/california-sushi-tapeworm-fresno-doctor-salmon

- http://www.onegreenplanet.org/animalsandnature/fish-the-new-factory-farmed-animals/

- http://www.timesunion.com/business/article/EPA-weighs-thousands-of-reactions-to-Hudson-PCB-12504822.php

- https://www.atsdr.cdc.gov/csem/csem.asp?csem=30&po=10

- https://www.fda.gov/Food/GuidanceRegulation/GuidanceDocumentsRegulatoryInformation/Seafood/ucm176892.htm

- https://www.foodnavigator-usa.com/Article/2017/12/21/Finless-Foods-co-founder-talks-clean-meat-clean-fish-cultured-meat

- ibid

- ibid

Pingback: Top 10 Articles of 2018 - Food Contact Surfaces